Chengdu Xinjin: SLANVERT Digital Smart Factory Aims to Fill Gaps in the Global I

Good News!

Located in the Tianfu Intelligent Manufacturing Industrial Park, one of the first advanced manufacturing enterprises in the Hope Tongyun Zhigu,

Hope Slanvert, has officially commenced operations at its newly built digital smart manufacturing factory.

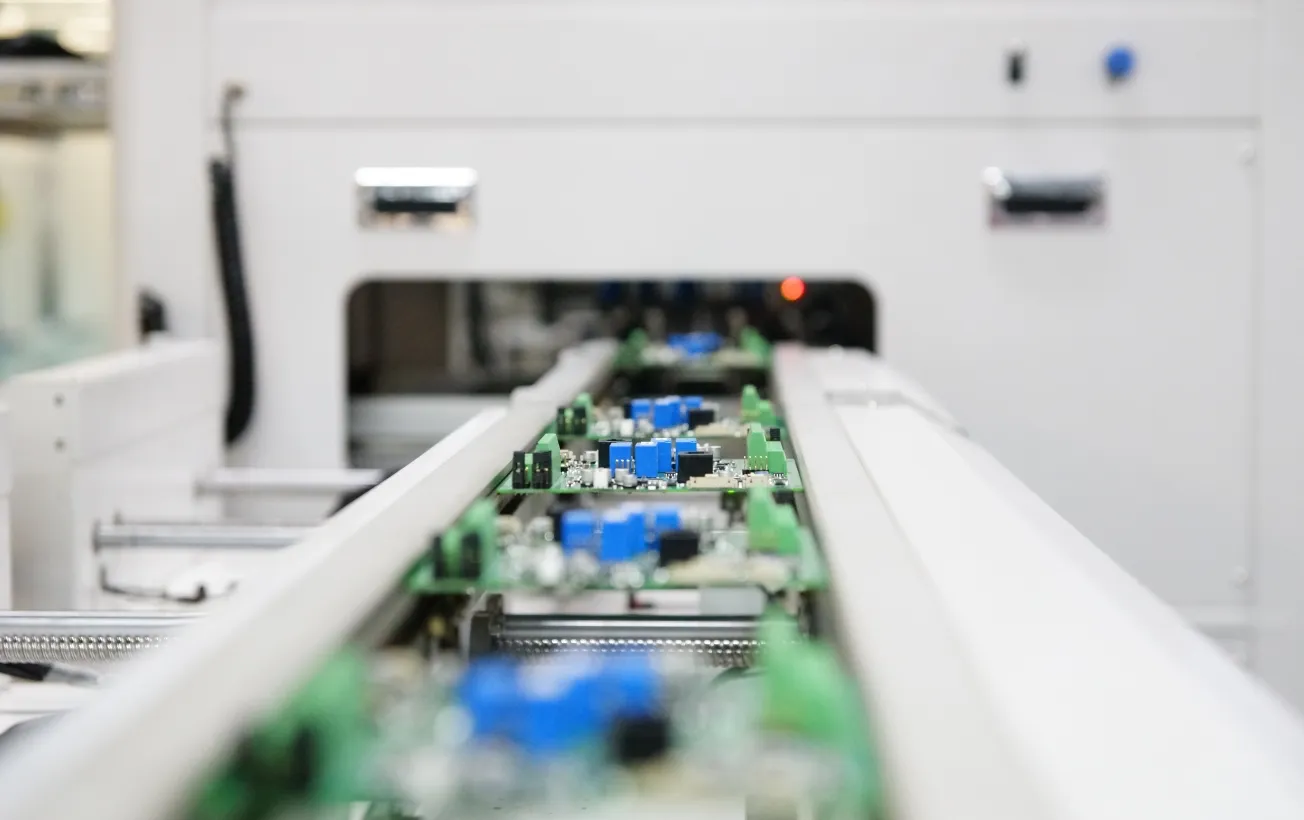

Inside this 30,000-square-meter digital factory, intelligent equipment is widely deployed, fully integrated with a comprehensive digital management system. On-site, the SMT systems operate with precision and efficiency—covering the entire process from solder paste printing, automated inspection, and component placement, to AOI (Automated Optical Inspection) before and after reflow soldering, and finally automatic board collection and packaging. Every step showcases a highly automated production workflow.

Meanwhile, AGV robots navigate the facility with agility, enabling efficient material handling. Robotic arms then carry out precise assembly, testing, and packaging tasks. Finally, products are systematically stored through an automated warehousing system. The entire process achieves full automation and standardization in the production of small and medium-sized products.

In the Operations Management Center, a large digital display screen provides real-time updates on key production metrics—including production progress, equipment status, product quality, and the Andon system for rapid issue detection and resolution. These data are accurately captured through the MES (Manufacturing Execution System) and presented in intuitive, easy-to-understand visual charts, allowing managers to quickly grasp production dynamics. In addition, detailed reports offer in-depth data analysis to support informed decision-making.

Notably, leveraging advanced Internet of Things (IoT) technology, the digital display also provides a clear overview of the operational status of every Slanvert product deployed worldwide. With this system, Slanvert's after-sales personnel can conveniently monitor and manage equipment from anywhere in the world via a mobile app.

As a leading Chinese enterprise in energy conservation, environmental protection, new energy, drive control, and intelligent equipment, Slanvert is recognized as the top domestic brand of variable frequency drives (VFDs). Its product portfolio covers high-, medium-, and low-voltage VFD control systems, which are widely applied across industries such as electric power, building materials, non-ferrous metallurgy, petrochemicals, equipment manufacturing, rail transit, new energy, and EV charging infrastructure. Slanvert's products have been exported to more than 30 countries and regions, including India, South Africa, Brazil, Italy, Denmark, Singapore, Indonesia, Malaysia, Vietnam, and Turkey.

You may also like

You may also be interested in

English

English 中文

中文

Leave a Message

Leave a Message