VFPS series variable frequency power supply application case

1. Application case of variable frequency power supply

1.1 3MW shore power system at Xiamen Ocean Container Terminal

As the first pilot project for port shore power supply in Fujian Province, the Xiamen Yuanhai Container Terminal, which meets the standards, has received high attention and support from the leaders of Fujian Province, COSCO Shipping Group and State Grid Xiamen Power Supply Company. It was officially put into operation on December 14, 2016, which means that in the future, ships docked at the Xiamen Yuanhai Container Terminal can be directly powered by shore power. Reducing pollution to the atmosphere and the ocean is of great social and economic significance for promoting the construction of green ports.

On the morning of March 7, 2017, as the huge ship EVERLISSOME LONOON slowly entered the Yuanhai Terminal of Xiamen Port, the new generation VFPS series outdoor containerized intelligent shore power supply system jointly developed by Hope Senlan Technology Co., Ltd. and Shanghai Ailinke Intelligent Technology Co., Ltd. officially embarked on its service journey. Subsequently, the staff on board the EVER LISSOME LONNON began to lay the high-voltage cables for ship connection. The onshore staff connected the high-voltage cables to the shore power junction box in berth area #14 of the port. EVER LISSOME LONNON has the conditions for connecting shore power. After checking the safety circuits connected on the ship, everything is ready. With the command of the ship's chief commander, it is hoped that the Senlan VFPS series shore power supply system will enter the one-click start program. At 11:19:05 a.m., the VFPS series shore power supply series officially entered the grid connection process. There was no impact during the grid connection process. The load was gradually transferred from the ship's generator system to the shore power supply system. Ten seconds later, the ship's generator system was successfully disconnected, and power was officially supplied by the VFPS series shore power supply. After 11 hours of continuous operation, the generator was connected to the grid again at 22:5 p.m., and the onshore power supply was successfully disconnected. Thus, the connection with the EVER LISSOME LONNON was successfully completed, and the connection was declared successful. This time, the shore power supply for the vessel was 14,823 kilowatt-hours. The maximum output power of the shore power source was 1,658 kilowatts, with an output voltage stability of 0.3% and an output frequency stability of 0.1%.

1.2 Jiaxing Port Jiahua Wharf 2MW low-voltage explosion-proof shore power system

"Woo——!" A long whistle broke the silence of the Jiagang Petrochemical Wharf, and a cargo ship full of oil slowly sailed into the berth. A terminal worker skillfully operated the cable reel truck, easily lifted the three cables to the port side of the freighter, connected them to the marine electrical box, and closed the switch. Immediately, the roaring auxiliary engines on the freighter stopped running, and the shore power provided green energy for the subsequent operation of the docked ship.

Explosion-proof cable reel car

Jiaxing Jiagang Petrochemical Terminal Co., Ltd. is a hazardous chemical transportation and logistics company, and ships arriving at the port must use ship auxiliary engines to generate electricity to meet the power demand on board. The auxiliary machine burns a large amount of oil during work, which will discharge a large amount of black smoke, resulting in environmental pollution and noise pollution. This not only affects the development and construction of the low-carbon ecology of the port, but also increases the risk of explosion and fire, which brings great challenges to the healthy and sustainable development of the terminal.

The front of Jiagang Petrochemical Terminal

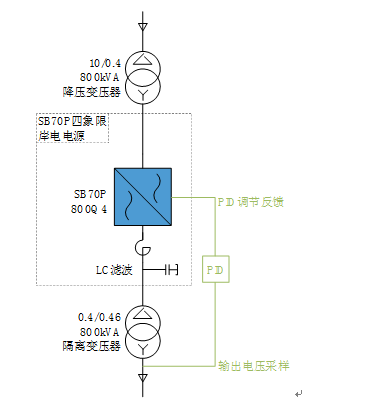

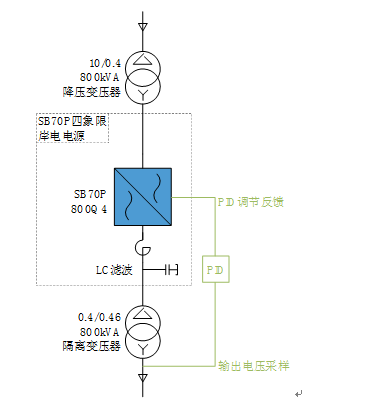

At the end of 2016, Hope Senlan Technology Co., Ltd. and Shanghai Ailinke Intelligent Technology Co., Ltd. jointly provided a newly designed SB70 explosion-proof intelligent shore power supply system solution for Jiagang Petrochemical Terminal. The system converts the 10kV/50Hz power supply into 440V/60Hz and 400V/50Hz variable dual-frequency dual-voltage output to the explosion-proof power connection box of the wharf.

This set of shore power system in the front of the wharf cable connection box and cable reel car design are the first in China to use the first explosion-proof design, explosion-proof level is IIBT4, in fact, most of the equipment explosion-proof level has reached IIBT6, in line with GB3836.1-2000 "Electrical equipment for explosive gas atmosphere". Part 1: General Standards, which is safer and more reliable than traditional shore power systems, and meets the shore power needs of hazardous chemical terminals. The core part of the system is two sets of Senlan SB70P series variable frequency power supplies, with a single capacity of 1MVA, and a DC common busbar scheme. Based on Sunland's 22 years of mature low-voltage platform technology, SB70P series low-voltage shore power conversion power supply is a new generation of high-performance variable frequency power supply customized and developed according to the application needs of shore power supply, which has the advantages of fast dynamic response, strong overload capacity and high control accuracy, and is second to none in terms of system topology selection, control performance, and heat dissipation system design.

Sunland SB70P series inverter power supply

After the completion of the shore power system, the power grid will supply power to marine equipment during the ship berthing and berth, replacing the traditional fuel oil for power generation, achieving zero emission of harmful gases and greatly reducing the proportion of ship emissions in the air pollution emission inventory. At the same time, it effectively reduces the transportation cost of the ship and improves the economic benefits. The shutdown of auxiliary engines during port calls will also reduce the vibration and noise of the ship, improve the quality of life of the crew and the environmental quality of the port area.

Normalize the ship

Based on the average daily ship docking for 16 hours and the average load of 200kW at Jiagang Petrochemical Terminal, a single ship can sell 1.168 million kWh of electricity per year after adopting shore power technology. In terms of fuel cost saving, the unit fuel consumption of diesel engines is about 250g/kWh, which can replace diesel by 292t (250g/kWh×1.168 million kWh) throughout the year. 1kg of diesel is about 1.16L, and the oil price is calculated according to 5.50 yuan/L, which reduces the cost of diesel fuel by 1.863 million yuan (292t×1.16L/kg×5.50 yuan/L) throughout the year. The annual electricity cost is 1.401 million yuan (1.168 million kWh× 1.2 yuan/kWh, note: 1.2 yuan/kWh is the unit price level after the catalogue electricity price plus service fee). The annual fuel cost of a single ship was saved by 1.863 million yuan - 1.401 million yuan = 462,000 yuan.

1.3 Part of the performance of inverter power supply products:

|

Username and address, zip code

|

Name of the goods sold

|

|

Johnson Controls Air Conditioning and Refrigeration Equipment (Wuxi) Co., Ltd

6000kVA air conditioner test bench

|

VFPS-110-6000-600 high-voltage variable frequency power supply

|

|

Suzhou Runyang Water Pump Co., Ltd

2500kVA water pump high voltage test power supply

|

VFPS-100-2500-150 high-voltage variable frequency power supply

|

|

Laboratory Building of National Water Pump and System Engineering Technology Research Center of Jiangsu University

2*900kVA high-voltage variable frequency power supply equipment

|

VFPS-100-900-095*2 mobile high-voltage variable frequency power supply

|

|

Guangzhou Xinheng Pump Manufacturing Co., Ltd

1800kVA test variable frequency power supply

|

VFPS-100-1800-150 high voltage variable frequency power supply

|

|

Johnson Controls Air Conditioning and Refrigeration Equipment (Wuxi) Co., Ltd

4000KVA high voltage inverter power supply

|

VFPS-110-4000-500*2 high-voltage variable frequency power supply

|

|

Changzhou Pacific Power Equipment Co., Ltd

1600kVA test power supply

|

VFPS-063-1600 High Voltage Variable Frequency Power Supply

|

|

Xiamen Port Ocean Terminal

3MW shore-based power supply project

|

VFPS-100-066-3000 High Voltage Variable Frequency Power Supply

|

|

Leibo Electric Appliance (Yueyang) Co., Ltd

1000kVA laboratory high voltage variable frequency power supply project

|

VFPS-038-100-1000 High Voltage Variable Frequency Power Supply

|

|

Jiaxing Port Jiahua Wharf

2MW low-voltage shore power supply project

|

SB70T1000H6*2 low-voltage inverter power supply

|

|

Ligang Wharf in Jiangyin City

800kVA low-voltage shore power supply project

|

SB70P 800Q6 low-voltage four-quadrant inverter power supply

|

|

Zhangjiagang City Port New Reloading Wharf

1000kVA low-voltage shore power supply project

|

SB70P1000Q6*2 low-voltage four-quadrant inverter power supply

|

|

State Grid Fujian Fuqing Jiangyin Port

3MW shore-based power supply project

|

VFPS-100-066-3000 High Voltage Variable Frequency Power Supply

|

|

State Grid Fujian Lianjiang Kemen Port

3MW shore-based power supply project

|

VFPS-060-066-3000 High Voltage Variable Frequency Power Supply

|

|

State Grid Fujian Xiamen Tongda Wharf

1MW shore-based power supply project

|

VFPS-100-066-1000 High Voltage Variable Frequency Power Supply

|

|

State Grid Fujian Xiamen Tongda Wharf

500kVA shore-based power supply project

|

SB70P500Q4 low-voltage four-quadrant variable frequency power supply

|

|

1MW shore-based power supply project of 13-15# berth in Legou District, Qinzhou City, Guangxi

|

VFPS-100-066-1000 High Voltage Variable Frequency Power Supply

|

|

Guangxi Qinzhou Port Dalanping 1-2# berth 3MW shore-based power supply project

|

VFPS-100-066-3000 High Voltage Variable Frequency Power Supply

|

|

Guangxi Qinzhou Port Dalanping 3-5# berth 3MW shore-based power supply project

|

VFPS-100-066-3000 High Voltage Variable Frequency Power Supply

|

|

Guangxi Qinzhou Port Dalanping North 1-3# Berth 3MW Shore-based Power Supply Project

|

VFPS-100-066-3000 High Voltage Variable Frequency Power Supply

|

|

Guangxi Fangchenggang 20-22# berth 2MW shore-based power supply project

|

VFPS-100-066-2000 high-voltage variable frequency power supply

|

2. Solutions to key problems in shore power systems

2.1 Reverse power control technology

2.1.1 The principle and hazards of inverse power generation

Mechanism of inverse power generation of shore power supply:

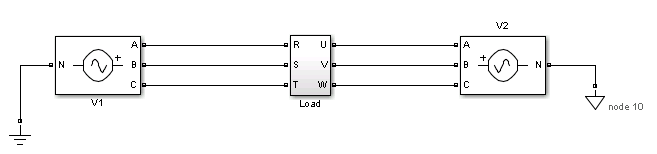

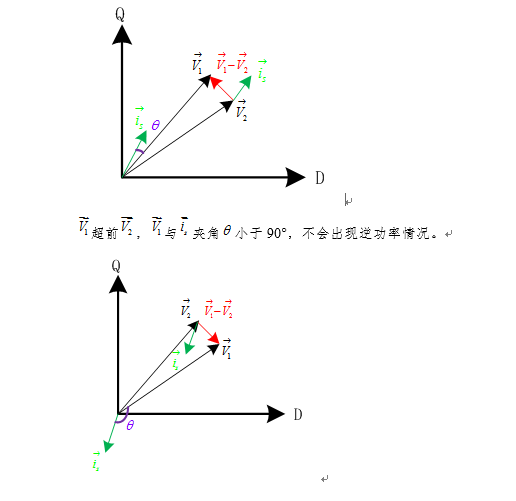

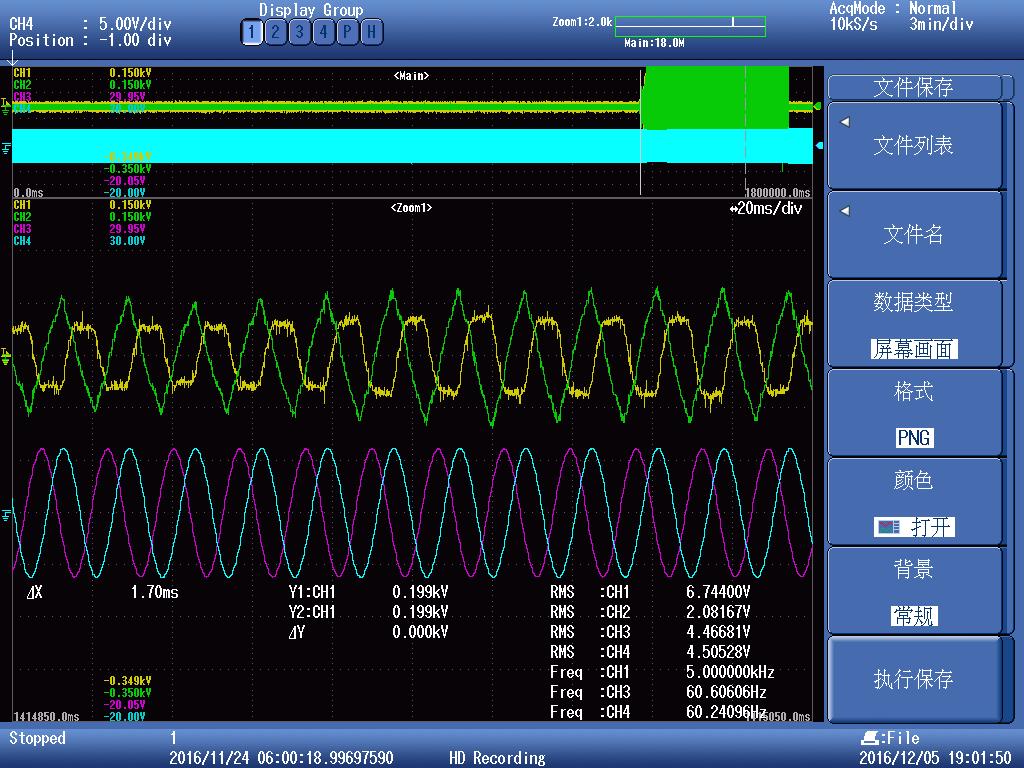

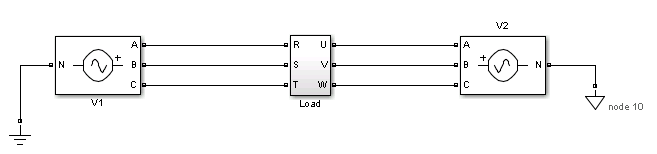

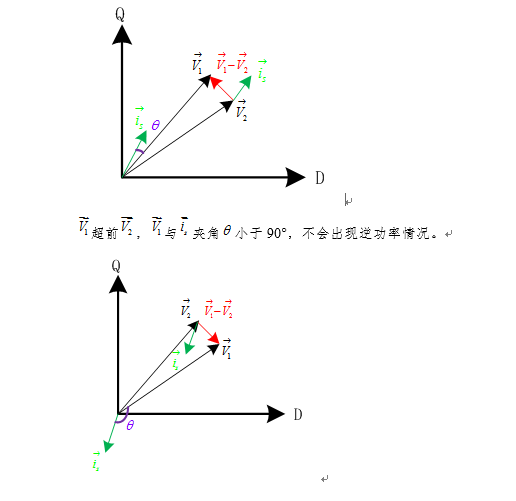

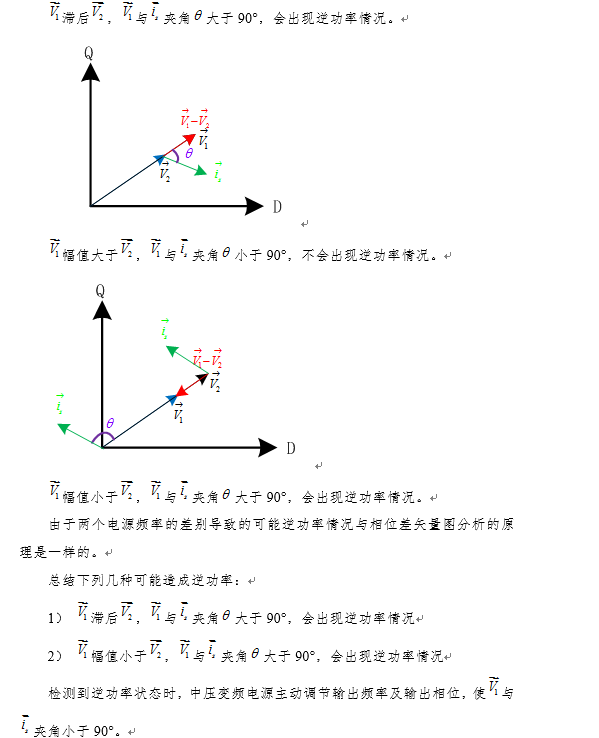

When two voltage sources supply a load at the same time, the reverse power due to the difference between phase, frequency and amplitude during grid-connected operation. The following is a vector diagram to analyze the mechanism of several reverse power generation, V1 is the shore power supply, and V2 is the generator power supply.

When the reverse power of the shore power supply system occurs, it will cause the bus voltage of the power unit to rise, and in severe cases, the system will report the "unit overvoltage" fault, which will lead to equipment shutdown. Affect the power supply quality of shore power supply.

2.1.2 Reverse power treatment scheme

The inverter power supply automatically detects the inverse power condition, and when the inverse power condition occurs, the inverter power supply automatically adjusts the output frequency and output phase of the inverter power supply, and adapts to the voltage change of the generator on board to achieve the purpose of inverse power control. The specific operation process is as follows:

When the output power is negative, the output voltage frequency and phase are adjusted in real time through the internal PID control algorithm, so as to achieve the reverse power suppression function.

In general, the software suppression control algorithm can effectively prevent the occurrence of reverse power events in the four-quadrant shore power supply with energy feedback. According to the principle, if the reverse power is not effectively released, it will eventually lead to an increase in the DC bus voltage. When the voltage value of the DC bus rises, the precise control of the DC bus voltage is realized through the active rectifier AFE front end, which can make the energy of the reverse power feedback feedback to the power grid through the feedback function, so as to ensure the reliability of the operation of the shore power supply system.

2.2 Reactive power suppression function

Based on the practice of vessel connection, at the moment when the generator is connected to the vessel and the grid, due to the certain differences in voltage and phase between the generator system and the shore power supply system, instantaneous reactive power is generated. If it cannot be controlled in time, it may lead to the failure of vessel connection. It is hoped that the latest VFPS and SB70P series of shore power supply dedicated power supplies developed by Senlan will have anti-reactive resonance functions and strong anti-shock capabilities. When selecting and designing the electrical system, the shock caused by grid connection reactive power should be taken into consideration. In the control stage, the voltage and phase are controlled in real time to avoid the failure of vessel connection.

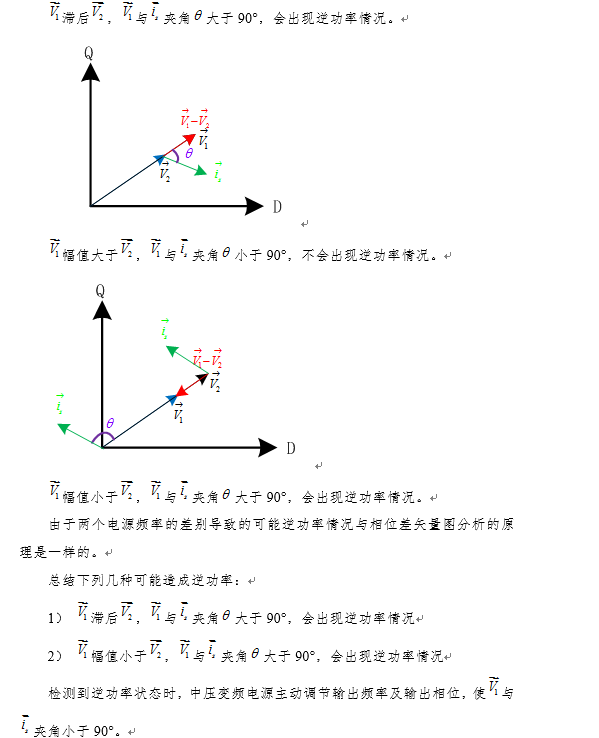

2.3 Automatic voltage stabilization function

The VFPS and SB70P series shore power supplies adopt voltage closed-loop control for output. By detecting the output voltage and feeding it back to the AI, the PID method is used to ensure the stability and accuracy of the output voltage. To adapt to unbalanced loads, each phase voltage is subject to individual closed-loop control. When the load is unbalanced, the load size of each phase can be independently allocated, thereby ensuring that the three-phase output voltages are balanced under unbalanced loads and preventing the electrical equipment on board from being affected by voltage fluctuations.

Due to the internal resistance of electrical equipment, there is a certain voltage drop in the output voltage of the shore power supply system. When the equipment load is high (the output current is large), the voltage drop increases accordingly, causing the system output voltage to fail to reach the expected value. In response to this phenomenon, the shore power variable frequency power supply adopts the PID regulation method to solve it. By monitoring the output power supply voltage value in real time and making adjustments, the accuracy of the system output voltage is ensured and the impact of system voltage drop is eliminated. The following figure shows the control scheme diagram of PID regulation:

The influence of system voltage drop is eliminated through the PID regulation method

The shore power system sets up an output voltage sampling point at the rear end of the output isolation transformer. After obtaining the real-time output voltage value through sampling at this point, the data is sent to the internal PID mechanism of the system for comparison. The result is then converted into a control instruction and sent to the shore power system. The shore power system regulates the output voltage. Eventually, the output voltage reaches the expected output value, and the voltage drop problem of the shore ship connection section system is solved.

2.4 Output synchronous tracking phase-locked

The shore power supply grid connection switching system is an important link in the ship's shore power system and also a technical difficulty. When shore power supplies power to berthed vessels, seamless switching between the vessel's power source and shore power can be achieved, eliminating the need for power outages on the vessel. The variable frequency power supply has a synchronous tracking phase-locking function. After the voltage, phase, and frequency output by the frequency converter are synchronized with those generated by the on-board diesel generator, it cuts in to supply power to the vessel's electrical equipment. This can ensure the safety of the electrical equipment on the ship and enable smooth and synchronous switching without affecting the use of the electrical equipment on the ship. It is hoped that the Senlan VFPS and SB70P series shore power supplies can choose active grid connection and passive grid connection. When active grid connection is chosen, the shore power supply monitors the voltage signal on board the ship and implements phase-locked tracking control, adjusting the output voltage size in real time. To prevent reverse power events, during control, the frequency and phase are deliberately advanced by a certain range before sending the grid connection signal, thereby achieving seamless switching with the ship's power generation system. When passive grid connection is chosen, the shore power supply system outputs a certain voltage. The ship's synchronization device detects the voltage between the shore power supply and the ship's power supply. When the grid connection conditions are met, a grid connection instruction is issued. At this time, due to the sampling accuracy of the grid-connected device on the ship, reverse power events may occur. When reverse power events happen, the shore power supply system can promptly detect the reverse power and adjust the voltage output, thereby preventing the occurrence of reverse power events.

2.4.1 Two grid connection methods

Active grid connection switching

The variable frequency power supply only serves as the main body for the entire power grid switching. Based on the information collected from the auxiliary generator on the ship, including voltage and current, the voltage signal is mainly used to standardize the output voltage of the variable frequency power supply. The output of the variable frequency power supply is frequency-locked and phase-locked, ensuring that the phase, frequency, amplitude, phase sequence, etc. of the output power supply are completely consistent with those on the ship.

The main function of current information is to let the frequency converter know the output power of the generator at this time and transfer the load. The frequency converter power supply can control the output, gradually increasing the output power until the load carried by the generator is completely transferred to the power supply of the frequency converter power supply.

Active grid connection currently has a small number of applications. Its advantage is that it can achieve the intelligence of the entire switching process, such as one-click switching, and all intermediate processes can be automatically completed.

The drawback is that the ship's cooperation is required for the renovation; otherwise, the voltage, current and other information of the generator cannot be known, and thus this system will not be more universal.

Passive grid connection switching

The variable frequency power supply only serves as a constant frequency and stable voltage power source, outputting voltage and frequency as required. All switching between power grids relies on the synchronization cabinet on the ship. The specific steps are as follows:

The frequency conversion outputs voltage/frequency according to the command requirements. The power supply is sent directly to the on-board frequency conversion power supply grid connection cabinet through output filtering, isolation transformer, interface box, and on-board incoming line cabinet. The grid connection cabinet displays the phase sequence, frequency, amplitude, phase and other information of the power supply based on the collected information, automatically determines whether the grid connection conditions are met, and adjusts the power generation information of the generator. Until the grid connection conditions are met, the variable frequency power supply is connected. After successful grid connection, the generator reduces the output power, and the load automatically and gradually shifts to the shore power supply for power supply. After the switching is completed, the generator stops working.

Passive switching is currently a popular and widely adopted solution because it has the characteristics of simplicity and universality, and can achieve the situation where a single power source supplies power to multiple ships simultaneously. However, the drawback is that at present, apart from the safety interlock signal, there is no other signal interaction between the ship and the shore-based power source, and the degree of automation is low.

2.4.2 Grid Connection Procedure

In the shore power supply grid connection switching system, the shore power is in a controlled and dominant position. Instructions such as grid connection and disconnection are all issued by the ship power system. Therefore, what the shore power needs to do now is to figure out how to make the electrical parameter requirements of the shore power system meet the requirements of the ship power system. The following procedures should be followed before the first grid connection operation:

1) Determine the basic electrical parameter requirements such as voltage and frequency of the ship's power supply;

2) Ensure the phase sequence confirmation before docking;

3) Ensure that the ship's load is within the load capacity of the shore power.

4) The safety circuit must be verified;

2.4.3 Issues to be Noted during grid connection

1) Grid connection may cause drift in output current, voltage and frequency, deviating from the grid frequency, resulting in unstable conditions and reverse power, and may contain relatively large harmonic components of voltage and current.

2) At the moment when shore power and ship power are connected to the grid, due to the different voltage phases, a relatively large inrush current may occur, causing damage to related equipment.

3) The shore power system should be equipped with overvoltage, undervoltage, frequency detection and protection functions, automatic grid isolation for overload and short circuit, and automatic reverse power detection and protection functions.

4) Reverse power protection device

The reverse power protection device is composed of a reverse power detector and an anti-reverse flow control system. The anti-reverse flow control system will constantly monitor the voltage and current. Once it detects that power is being fed to the grid and shore power, the anti-reverse flow control system will take effect to prevent the grid from supplying power to the shore power system. Ultimately, grid-connected operation, load transfer and de-listing are achieved without the occurrence of reverse power. If a faulty reverse power is generated, the shore power system will trip for reverse power protection.

2.4.4 The process of grid connection for shore power supply

The shore power system is connected to the grid

After the shore power is supplied to the ship, turn on the shore power grid connection switch. The ship's paralleling cabinet will confirm the phase sequence and the three essential elements for grid connection: voltage, frequency and phase Angle.

2) When the grid connection conditions are met, close the grid connection switch of the auxiliary engine on board.

3) Automatically transfer the load to the shore power through the ship power system;

4) Automatic disconnection of Marine and electrical auxiliary equipment;

5) Run under load by shore power.

The auxiliary equipment of the ship and electricity is connected to the grid

1) The three essential elements for grid connection, namely voltage, frequency and phase Angle, are confirmed by the vessel paralleling cabinet.

2) When the grid connection conditions are met, close the grid connection switch of the auxiliary engine on board.

3) Automatically transfer the load to the auxiliary equipment of the ship's electrical system through the ship's electrical system;

4) Automatic disconnection of the shore power system;

5) It is operated under load by the ship's electrical auxiliary equipment.

2.5V /F complete separation control technology

In variable frequency power supply scenarios, it is necessary for the frequency converter to output different combinations of voltages and frequencies, and the load is not entirely motor type. Therefore, for variable frequency power supplies, it is necessary to have V/F complete separation control technology.

The VFPS and SB70P series shore power variable frequency power supplies have this function, which can achieve separate control of voltage and frequency, and independently adjust voltage and frequency according to actual conditions.

2.6 Three-phase Load Imbalance Control Technology

Because the load of the variable frequency power supply is different from the motor-type load of the frequency converter, the use of single-phase load on the ship makes it impossible for the load distribution among the three phases to be absolutely balanced, and thus the voltage drop between each phase may be different. The variable frequency power supply is equipped with three-phase output unbalance control technology, which can achieve closed-loop control of voltage unbalance degree. Even when the three-phase load unbalance degree reaches 30%, it still maintains symmetrical output of three-phase line voltage.

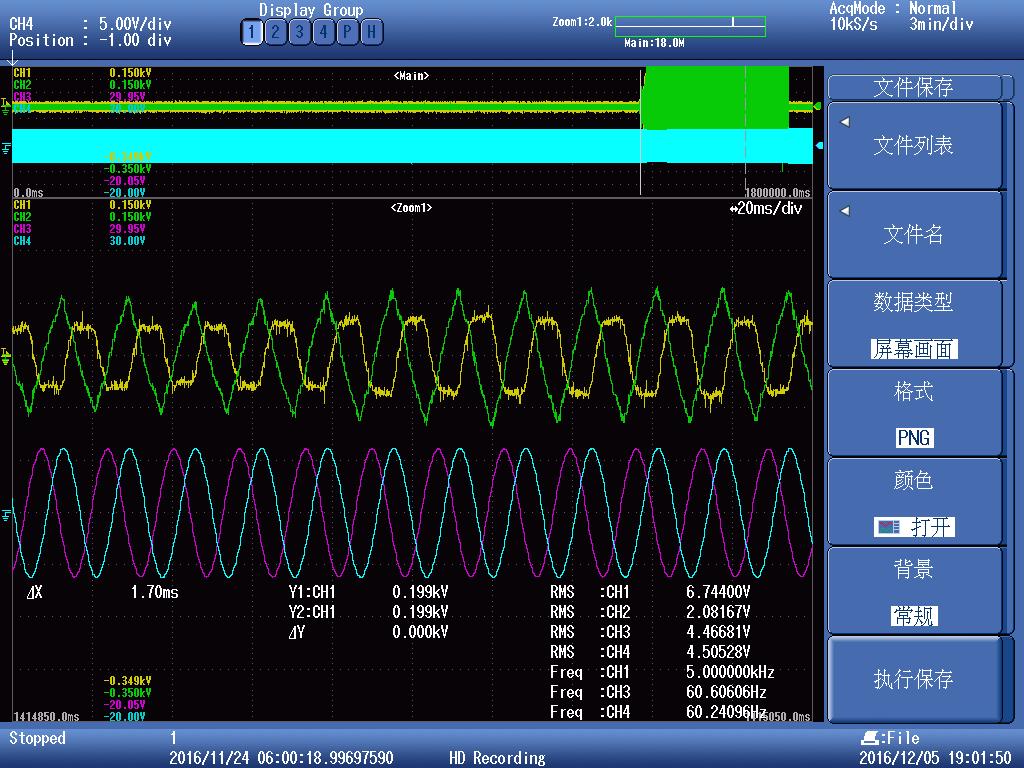

Output waveform of unbalanced voltage for three-phase load

From top to bottom, they are: two-phase output current, two-phase output voltage. It can also be seen from the cluster waveform that when the three-phase load is unbalanced, the three-phase voltage remains balanced.

2.7 Anti-excitation inrush current technology

The variable frequency power supply contains many electrolytic capacitors inside, which are affected by its characteristics. At the moment of power-on, it is equivalent to a short-circuit state, with a certain inrush current, which may damage rectifiers, electrolytic capacitors and other devices. To limit this charging current, it is necessary to prevent excitation inrush current. An important component of high-voltage variable frequency power supply, the phase-shifting transformer. Due to its characteristics, a large excitation inrush current will be generated at the moment of power-on, which will have a certain impact on the upper-level high-voltage switch cabinet. To reduce the impact, it is necessary to prevent the excitation inrush current. During the anti-excitation inrush current pre-charging process, it is also a self-checking process for the power unit, which helps to detect abnormal states of the power unit in advance.

(1) Three-side charging method of the transformer:

The pre-charging process lasts for up to 30 seconds and requires the implementation of many solidified logical processes to be achieved.

The position and status of the grounding knife in the upper-level high-voltage switch cabinet need to be taken into consideration.

(2) Charging method on the primary side of the transformer:

The electrical principle design is simple and clear, and the reliability of charging is high.

The pre-charging process takes 3 seconds and can be automatically controlled.

The Senlan VFPS and SB70P series variable frequency power supply transformers adopt a direct charging mode on the primary side. By adding current-limiting resistors and bypass contactors on the primary side, high voltage is directly applied to the current-limiting resistors to achieve the effect of current limitation. At this point, after power-on, the voltage rises slowly and the inrush current is controllable. When the voltage reaches 70% of the rated voltage, the bypass vacuum contactor automatically operates to bypass the current-limiting resistor, and the equipment is powered at full voltage. When there is no vessel connection, the system loss is close to zero. When it is necessary to connect vessels, at the moment of closing the high voltage, no inrush current occurs and there is no limit to the number of times the lock can be closed.

2.8 Space Voltage vector SVPWM modulation technology

The Senlan SB70P series shore power supply adopts SVPWM space voltage vector modulation technology. The level of the carrier frequency determines the accuracy of the output current of the frequency converter. To ensure the high-precision output of the current, the carrier of the ship shore power frequency conversion power supply needs to be set above 4k. Increasing the carrier frequency can effectively suppress harmonics, but at the same time, it leads to excessive heat generation of IGBT. Therefore, the variable frequency power supply needs a targeted solution. The Senlan SB70P series low-voltage shore power variable frequency power supply adopts the unique SVPWM spatial voltage vector modulation technology, which solves the heat generation problem. While reducing switching losses, The output current harmonic is guaranteed to be below 4% through the front-end input reactor and the LC filter at the output end.

2.9 Intelligent Expansion Technology

Considering the subsequent batch construction of shore power and the technical requirements of multi-machine large-capacity paralleling, we will look at the shore power system as a power grid. Sunland's VFPS and SB70P series shore power supply systems can expand the total capacity of the system by connecting multiple systems in parallel in the later stage according to the actual needs of users. For example, if the original system capacity is 1.7MVA, it can be expanded to a 5.1MVA capacity system by adding two sets of 1.7MVA shore power supply equipment.

The whole expansion system is composed of multiple box-type integrated shore power, the containers are placed side by side, and each box-type integrated shore power is connected through optical fiber communication, and the power balance, load balance, and synchronous coordination control are realized through the shore power control system and output synchronous tracking lock-in technology, which perfectly solves the needs of the later expansion of the system. When the output capacity of the system is insufficient, it can be automatically connected to the grid for expansion, automatically cut off when the capacity is surplus, and automatically cut off and derate when a single unit fails. The fieldbus supports Modbus, CAN, Profibus-DP, Ethernet, and other communication modes. The performance parameters of the entire system will not be reduced after the entire system is expanded.

Xiamen Ocean Terminal 3 x 1.7 MW intelligent expansion solution

English

English 中文

中文

Leave a Message

Leave a Message