The application of Sunland high-voltage inverter in urban central heating Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Download

- Contact us

The application of Sunland high-voltage inverter in urban central heating Solution

Features and Benefits

Keywords: Sunland high-voltage inverter heating

Abstract:It is hoped that the application of the third generation of Sunland high-voltage inverter in the Dun'an Laiyang renewable energy urban central heating project (hereinafter referred to as Dun'an heating), the Dun'an Laiyang heating project is divided into two phases, using a total of 16 Sunland high-voltage inverters, this paper focuses on the application of Senlan high-voltage inverter in the first phase of Dun'an Laiyang heating project 4 induced draft fans, 4 feed pumps, and 3 heat network circulating water pumps.

1. Background

With the rapid development of Laiyang in recent years, the current heating capacity of Laiyang City is far from meeting the needs of urban development, the current gap of 1.5 million square meters, and the annual growth rate of 10-200,000 square meters, at the same time, Laiyang Juli Fine Chemical Co., Ltd. has a large amount of circulating cooling water waste heat can be utilized, so DunAn (Tianjin) Energy Saving System Co., Ltd. plans to build a new heat network near Juli Chemical Plant, and recover the waste heat in Juli circulating cooling water through steam drive heat pump technology for heating in Laiyang urban area.

The traditional induced draft fan, primary fan, feed pump and heat network circulating water pump of thermal power plant usually achieve the purpose of changing the flow rate by adjusting the opening of the valve, this method makes a large amount of flow consumed on the valve, the regulation efficiency is low and uneconomical, and the equipment loss is large at the same time, the operation and maintenance cost is high, with the wide application of high-pressure frequency conversion governor, Senlan high-voltage inverter is a reliable product with high quality, high efficiency and high energy saving.

2. Project Overview

Dun'an Laiyang Heating Co., Ltd. is located in Laiyang Development Zone, adjacent to Fushui North Road in the north, Juli Fine Chemical in the west, Laixue Road in the east, and farmland in the south. The company is a renewable energy heating enterprise integrating energy saving, environmental protection and comprehensive utilization of waste heat reuse, covering an area of more than 200 acres, with more than 100 workers, an annual heating load area of 8 million square meters, and an average annual heating capacity of 3.15 million GJ. The heating project adopts heat pump technology to recover the heat of cooling water (temperature 32 °C, water volume 13,100t/h) adjacent to Juli Fine Chemical Co., Ltd., and the first phase of the project is constructed with 6 heat pumps (6MW steam dragging × 6 heat pumps), and 2×75t/h circulating fluidized bed boiler + 1×12MW back-pressure generator set is reserved to gradually meet the requirements of 8 million square meters of heating and 150t/h steam supply in Laiyang City.

1. Overview of heating process

The heating process mainly includes combustion system, coal conveying system, slag removal system, water supply and water replenishment system, desulfurization and dust removal system, chemical water treatment system, electrical system, etc.;

Boiler parameters: rated evaporation capacity: 75t/h main steam pressure: 3.82MPa main steam temperature: 450°C feed water temperature: 104°C Boiler design thermal efficiency: 89%

(Figure 1) 6×75t/h Dun An Laiyang heating plant area map

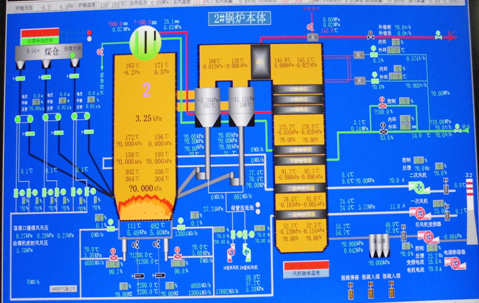

(Figure 2) Schematic diagram of the operation of the boiler unit

1.1 Combustion system: including coal feeding system, air supply system, flue gas system, limestone system, ignition system;

1.2 Coal conveying system: including off-site transportation of coal-fired plants, boiler combustion, coal unloading and coal storage facilities, screening equipment, and coal transportation systems;

1.3 ash removal system: including mechanical slag removal system and pneumatic ash removal system;

1.4 The desulfurization adopts limestone gypsum wet desulfurization technology, and the desulfurization efficiency is 99.6%; The dust removal is carried out by a bag dust collector, and the dust removal efficiency can reach more than 99.9%;

1.5 water supply system: including water supply sources, circulating water demand, etc.;

1.6 Fans and pumps: mainly including primary fans, secondary fans (low pressure), return fans (low pressure), induced draft fans, feed pumps, condensate pumps (low pressure), heat network circulating water pumps, etc.;

1. Selection of high-voltage inverter

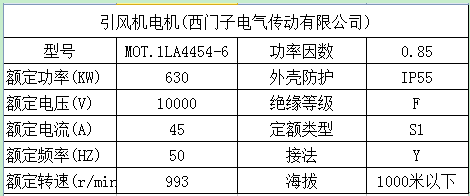

(1) 75t/h circulating fluidized bed boiler induced draft fan and motor parameters

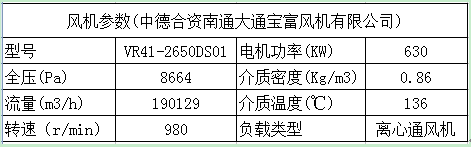

Induced draft fan parameters

(2) Parameters of heat network circulating water pump and motor parameters

Circulating water pump parameters

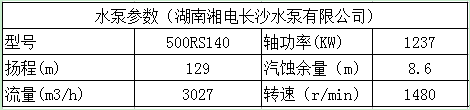

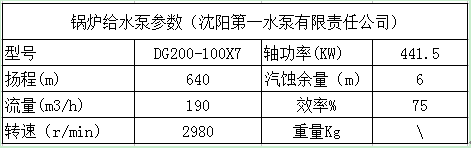

(3) 75t\h boiler feed pump motor and pump parameters

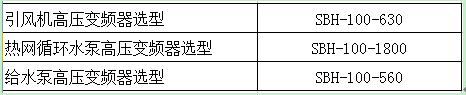

The fans and pumps of thermal power plants are all square torque loads, and the selection is as follows with reference to the process conditions and the technical advantages of the third-generation high-voltage inverter of Sunland:

(Fig. 3) Schematic diagram of the boiler induced draft fan

(Fig. 4) Heat network circulating pump in operation

(Fig. 5) Feedwater pump in operation

(Fig. 6) Induced draft fan in operation

(Fig. 7) Circulating water pump of the heat network in operation

(Fig. 8) Feed pump in operation

3. Primary system scheme

Sunland high-voltage inverter one-to-one manual bypass system diagram

Sunland's third-generation high-voltage inverter has three isolation switches inside the switch cabinet of manual one-to-one, and the cabinet door is equipped with high-voltage live display and electromagnetic locking device, the cabinet door is equipped with interlocking action protection device, and the mechanical interlock device is used between QS2 and QS3, which not only meets the requirements of safe and stable operation of the equipment, but also ensures the safety of personnel operation, QS1 is the high-voltage input side knife switch of the inverter, QS2 is the knife switch that the inverter outputs directly to the motor, and QS3 is the bypass knife switch for power frequency operation; When frequency conversion: after manually closing QS1 and QS2, close the cabinet door, and send a signal to the upper high-voltage switchgear to allow closing after the system self-test is normal; Power frequency: Manually close QS3 and disconnect QS1 and QS2, and the higher-level high-voltage switchgear can receive the signal that allows closing; It should be noted that the isolation switch is strictly forbidden to operate with high pressure and load;

3. Operation

The project is a heating project built by DunAn (Tianjin) System Energy Saving Company in Laiyang, due to the long-term cooperation between DunAn Energy Saving System Company and Hope Sunland Technology, it is also a loyal customer of Sunland inverter, Sunland inverter customer service combined with the actual situation of the heating project under DunAn Energy Saving System Company, tailor-made "butler" full service mode for the customer, the project from November 6, 2014 to December 28, 2014 No. 1 furnace, No. 2 furnace began to heat supply, Senlan high-voltage inverter operation is stable, And with DCS to achieve automatic control, from the site operating conditions, fan, pump load adjustment is smooth and stable, energy-saving effect is obvious, customers give a very high evaluation.

Fourth, summary

In the cogeneration industry, the high-voltage motor as an important auxiliary equipment for the stable operation of the boiler, but also the power source of the whole plant, Sunland high-voltage inverter in the cogeneration project of a large number of applications, at the same time in electric power, metallurgy, building materials, chemical industry, biopharmaceutical, municipal engineering and so on have a large number of wide applications, not only shows that Sunland high-voltage inverter is a high-quality, high-efficiency, high-energy saving environmental protection products, but also shows that Sunland inverter has made contributions to China's energy conservation and environmental protection.

Related Products

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|

English

English 中文

中文

Leave a Message

Leave a Message