The application of SBH Series high-voltage frequency converters in the boiler an Solution

Overview

- Overview

- Features and Benefits

- Related Products

- Download

- Contact us

The application of SBH Series high-voltage frequency converters in the boiler an Solution

Features and Benefits

Application of SBH series high-voltage frequency inverter in Guangxi Mingyang boiler and circulating water system

Guangxi Mingyang Biochemical Technology Co., Ltd. is located in Mingyang Industrial Park, Jiangnan District, Nanning City, the capital of Guangxi. Founded in 1958, it is a high-tech enterprise, a national key leading enterprise in agricultural industrialization, and a national leading enterprise in poverty alleviation. Passed ISO9001 quality system certification in 1997. The company is mainly engaged in seven major industries, including planting and promotion of improved cassava seeds, deep processing of starch and alcohol, fertilizers, e-commerce, paper molds, machinery manufacturing, and logistics. Its leading products include "Tanfeng", "Mingyang" brand cassava starch, and cassava modified starch. , alcohol, paper molds, and machinery. The products are mainly used in papermaking, textiles, food, medicine, building materials, feed, petroleum and other industries; the annual production scale of starch is 200,000 tons and alcohol is 50,000 tons. It is currently the largest integrated R&D company in China. A cassava modified starch manufacturer integrating production, sales and application technology services. The company uses Guangxi's unique cassava resources to integrate and establish a business model of "company + scientific research unit + raw material base + farmers" that combines production, academia and research. It uses scientific and technological innovation to change farmers' scattered and extensive planting management model and drive farmers to pursue scientific and technological development. roads, steadily increasing the income of farmers, and playing a leading and exemplary role in promoting the development of the local rural economy. Currently, it has 6,000 employees, including 200 technical personnel.

In order to respond to the national call for energy conservation and consumption reduction and improve production efficiency and system stability, the company carried out frequency conversion energy-saving transformation on its 75T boiler system and 100,000 tons alcohol circulating water system.

2. Introduction of operating conditions

2.1 Boiler Condition

Involved motor Parameter

| Device Name | Мotor | Rated Speed (r/min) | Rated Power (KW) | Rated Voltage (KV) | Rated Current (А) | Quantity (set) |

| Primary fan | YKK4506-4 | 1483 | 400 | 10 | 28.7 | 1 |

| Secondary fan | YKK4503-4 | 1482 | 280 | 10 | 21 | 1 |

| Induced draft fan | YKK5002-6 | 988 | 400 | 10 | 29.8 | 1 |

| Feed pump | YKK4507-2 | 2984 | 450 | 10 | 32.14 | 2 |

Load parameters:

| Device Name | Model | Flow rate | Full pressure/head | Rotational speed | Shaft power |

| Primary fan | G15-16 | 85500 m3/min | 14900 pa | 1450 r/min | 400 KW |

| Secondary fan | R15-16 | 15590 m3/min | 8450 pa | 1450 r/min | 280 KW |

| Induced draft fan | Y15-16 | 198000 m3/min | 4790 pa | 960 r/min | 400 KW |

| Feed pump | DG85-80*12 | 85 m3/h | 960 m | 2950 r/min | 450 KW |

2.1.1 Introduction of operating conditions

At present, the main function of the 75T boiler system is to generate steam. The steam is first used for back pressure power generation and then sent to production. The steam is mainly supplied to the starch production line and the 100,000-ton alcohol production line. The steam production is adjusted according to the demand of the gas consumer unit. As far as current usage is concerned, the steam output fluctuates between 60T and 75T. In some periods, the output will drop to around 40T.

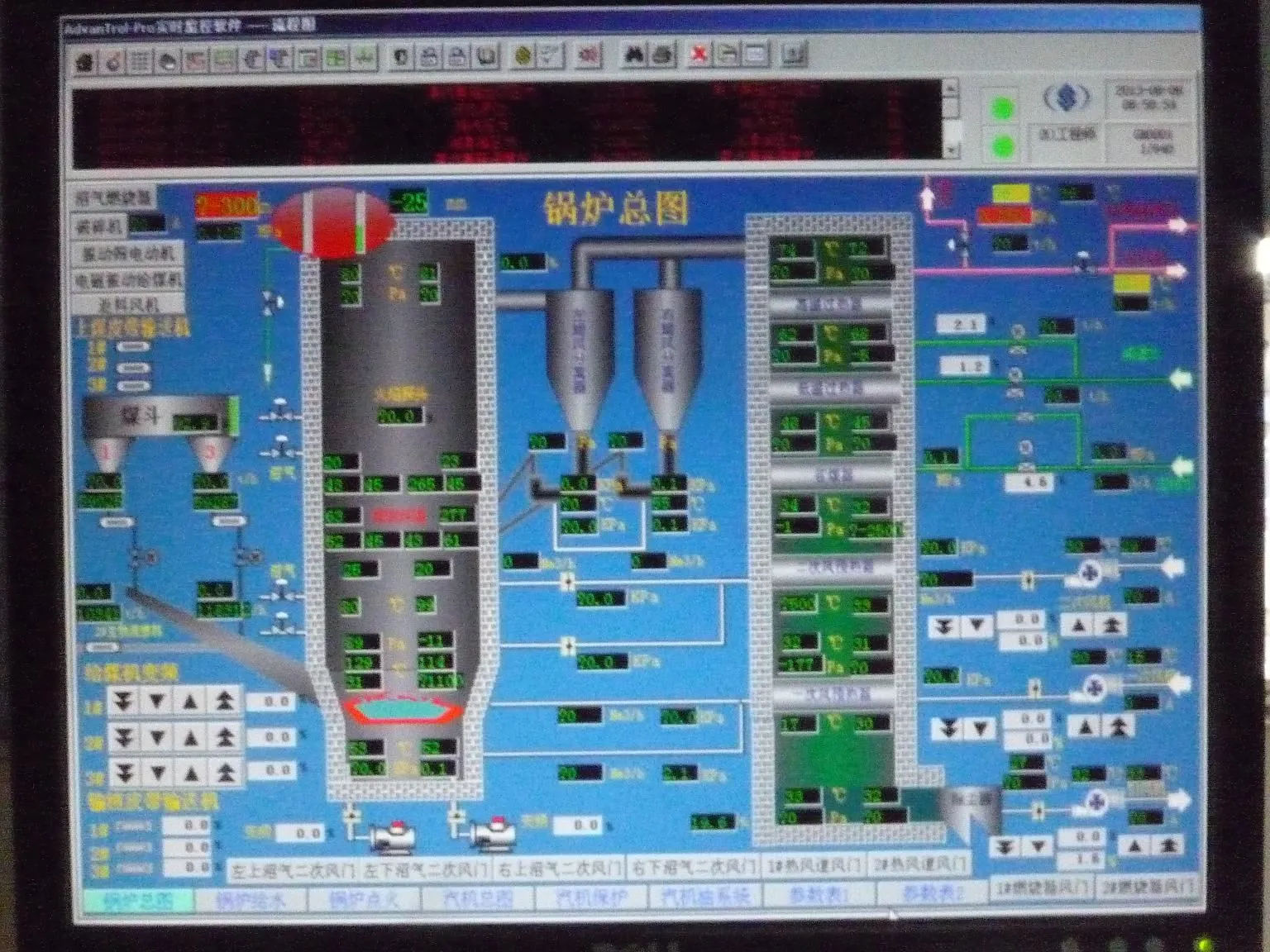

The adjustment of the boiler system load is mainly achieved by increasing the coal delivery volume and simultaneously adjusting the water pump to increase the water volume. In daily use, it is also necessary to adjust the valve opening changes of the primary fan, secondary fan, and induced draft fan to ensure reasonable furnace negative pressure and air supply volume. The above adjustments are remotely controlled through the control system of the monitoring center. The system monitoring interface of the boiler is shown in the figure below:

User DCS

Through the actual monitoring data display of the monitoring system and viewing the management logs for a period of time in the past, under different production loads. The operation conditions of the fan and water pump of the 75T boiler system are as follows:

| / | 75T capacity | 65T capacity | 50T capacity | 40T capacity | ||||

| Device Name | Valve opening | Current | Valve opening | Current | Valve opening | Current | Valve opening | Current |

| Primary fan | 43%~50% | 18A | 40%~50% | 18A | 40%~45% | 17A | 40%~45% | 17A |

| Secondary fan | 43%~50% | 13A | 30%~36% | 12A | 8%~12% | 10A | 0.09 | 10A |

| Induced draft fan | 75%~84% | 22A | 60%~80% | 22A | 0.57 | 19A | 0.48 | 18A |

| Feed pump | 30%~50% | 26A | 30%~50% | 25A | 30%~50% | 25A | 30%~50% | 25A |

The feed water pressure is 8.5~9.5 MPa, the drum pressure is 4.5~5.3 MPa; the feed water flow rate is 25~50 t/h; the primary fan outlet wind pressure is 7.4~8.1 KPa, the secondary fan outlet wind pressure is 1.1~1.3 KPa, and the induced draft fan outlet negative pressure When the valve is 80%, it is about -3700 KPa, and when the valve is 50%, it is -2000 KPa.

Turbo-Generator Set

Basic situation of 100,000 tons alcohol circulating water system

Involved Parameter of Motor and Load Equipment

| Device Name | Motor | Rated Speed (r/min) | Rated Power (KW) | Rated Voltage (KV) | Rated Current (А) | Quantity (set) | Rated Speed (r/min) |

| 3# Circulating pump | Y450-6 | 990 | 400 | 10 | 29.2 | 1 | |

| 4# Circulating pump | Y450-6 | 990 | 400 | 10 | 29.2 | 1 |

The two motors have same parameters with same load equipment. See below:

Name: Double suction centrifugal pump; Model Number:500S-59A ; Flow Rate: 2009 m3/h;

Lift:45m, shaft power:400KW, RPM: 970r/m. manufacturer: Shanghai Eastern Pump Co.,Ltd

2.2.1 Introduction of Operating Conditions

There are 4 water pumps in the 100,000-ton alcohol circulating water system. The 3# and 4# circulating water pumps are being transformed during this construction. Usually, the number of operating circulating water pumps is adjusted according to weather changes, the commissioning of production equipment, and load conditions. Mostly run 2 units. When the outside temperature rises or the production load increases, increase the input number of circulating water pumps.

The core indicators of circulating water are pressure and outlet water temperature. The actual adjustment of water supply volume is adjusted based on changes in external temperature and heat exchange requirements of the production line. The process requirements stipulate that when the mother liquor tank is circulated and supplied as heat exchange medium, the temperature of the circulating water near the mother liquor tank should be lower than 32°C. When the circulating water temperature is higher than 32°C due to the influence of ambient temperature, the heat exchange medium of the mother liquor tank is changed to low-temperature cold water from the freezer. The cooling circulating water of the circulating water station continues to be supplied to other systems, but the temperature should not be higher than 40°C. During actual use, adjust the opening of the water pump valve to ensure that the running current of the water pump motor is around 25A. The water outlet pressure is guaranteed to be 0.42MP.

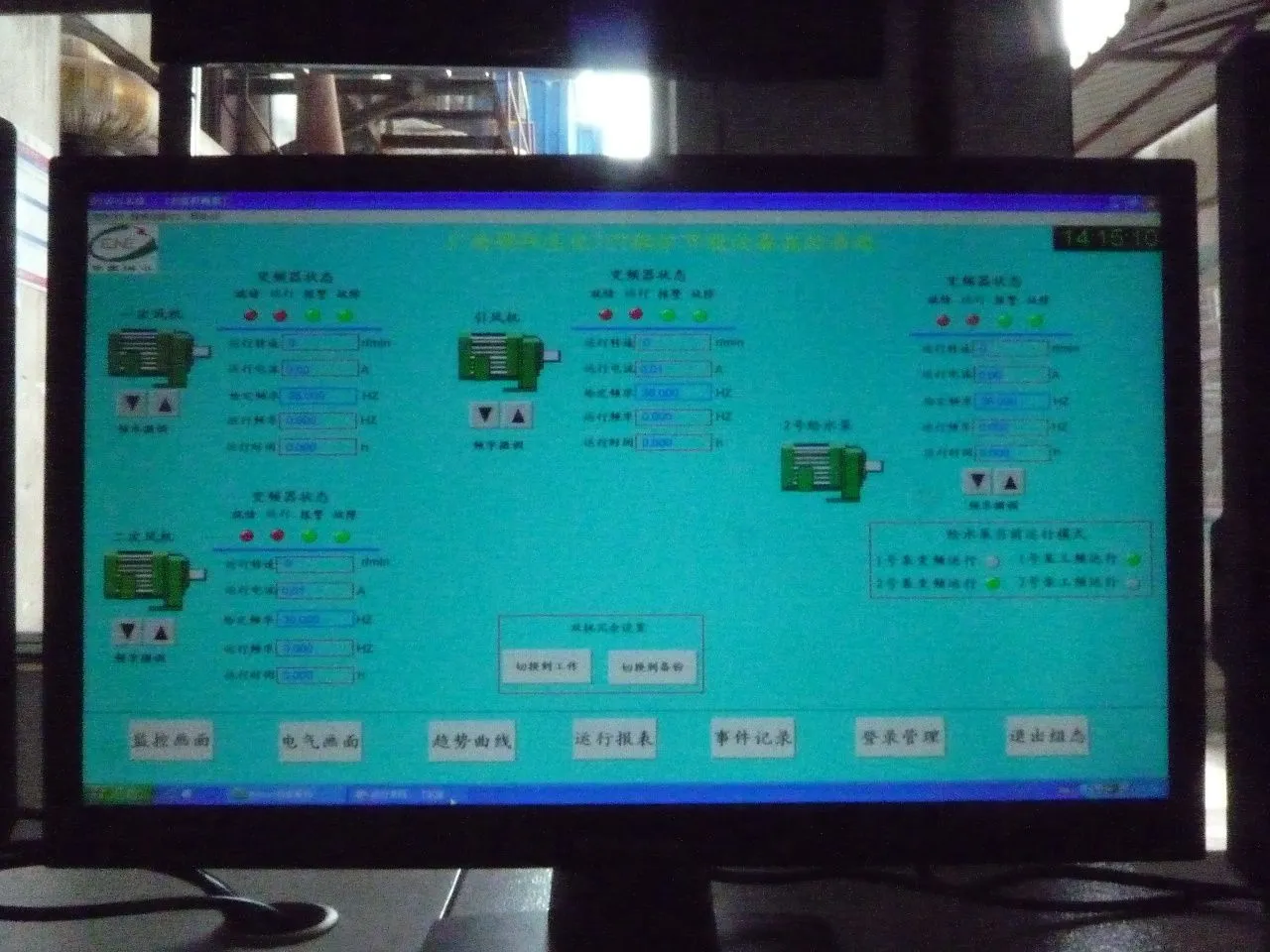

Circulating water pumping station

3. Introduction of energy-saving transformation plan and system control plan

For a long time, the company has been using very backward valve and baffle adjustments. Although simple and easy to implement, this extensive adjustment method comes at the expense of increasing pipe network losses and consuming a large amount of electric energy. For high-voltage and high-power motors, it is even more prominent. In view of this, users should make careful choices and considerations. Finally, it was decided to use SLANVERT high-voltage frequency converter to carry out frequency conversion energy-saving transformation of its 75T boiler system and 100,000-ton alcohol circulating water system.

4. Features of SLANVERT High Voltage Inverter

01. The main topological structure scheme selects a unit series structure, and uses low-voltage frequency conversion technology to achieve high-voltage output in series.

02. SLANVERT has nearly 20 years of experience in inverter development. Through continuous accumulation, it has accumulated a lot of experience in practice.

03. The production process is guaranteed. SLANVERT is a professional manufacturer of inverters. It is one of the earliest units in China engaged in the R&D and production of inverters and has accumulated rich experience in the production of power electronic products.

04. The core components of SLANVERT inverters are all internationally renowned brands, such as German EUPEC for IGBT, EPCOS for capacitors, MICROSEMI for rectifier bridges, and EBM for fans.

05. As for testing methods, SLANVERT has complete inverter testing equipment and testing methods, and a full-power test bench that can detect up to 10,000KVA to ensure that each device has been fully tested before delivery.

For after-sales service, SLANVERT has more than a dozen branches and nearly a hundred offices across the country. We have a professional after-sales service debugging team with rich on-site debugging experience.

Related Products

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|

English

English 中文

中文

Leave a Message

Leave a Message