Hope130 series is a delicate and practical inverter launched by Hope Sunland, with exquisite and small appearance, exquisite and perfect circuit, simple and practical functions, and clear and reasonable menu division.

Product Features:

■ Minimalist design

Thin and long look in accordance with the golden section, with rational internal component layout and strong anti-electromagnetic interference capability;

■ Extremely high power density

Small and exquisite, with ultra-high power density, largely reducing the demand for installation space;

■ Extremely high control performance

Optimized space voltage vector control for greater starting torque and better deceleration performance;

■ Very simple operation interface

Internationally popular RJ45 crystal-head plug for connection, with brand new industrial design, facilitating assembly, disassembly, and operation;

■ Ultimate quality assurance

24-year experience in industrial R&D and application and standardized design circuit, realizing the ultimate quality;

■ Excellent warranty service

The company took the lead in introducing the golden key service system and realized the nationwide warranty service, erasing all potential worries for its customers;

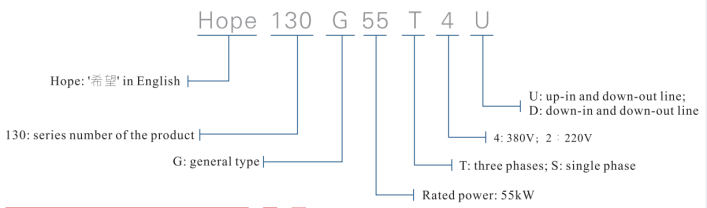

Product specification:

Items | Item Description | |

Input | Rated voltage, frequency | Single phase: 220V; Three-phase: 380V, 50Hz/60Hz |

Allowable range | Voltage fluctuating range: -15%~10%; voltage unbalance:<3%; frequency: 47Hz~63Hz | |

Output | Output voltage | Three-phase, 0V~input voltage, tolerance<5% |

Output frequency range | 0.00-650.00Hz | |

Performance indicator | Overload capacity | 150% rated current for 1 minute |

Frequency resolution | Digital setting: 0.01Hz; simulation setting:<2% of the maximum frequency | |

Output frequency accuracy | Simulation setting: <±2% of the maximum frequency; digital setting: 0.01Hz | |

Control terminal | Analog input AI | 2 circuits of AI, with voltage type and current type independent terminal available and disconnection detection function |

Analog output AO | 2 circuits of multifunctional AO, with voltage type and current type independent terminal available | |

Digital input | 6 circuits of multifunctional digital input | |

Digital output | 1 circuit of OC multifunctional digital output and 2 circuits of multifunction relay output | |

Communication | Built-in RS485 communication interface, with optional terminal resistance, supports RTU mode and Modbus protocol | |

Software functions | Motor control mode | High-performance optimized-space V/F control with functions including automatic torque lifting, slip compensation |

Run command channel | Operation panel setting, control terminal setting, communication setting, switchable via terminal | |

Frequency setting channel | Operation panel, communication, UP/DOWN regulated value, and AI can achieve auxiliary frequency superposition and trimming | |

V/F curve | Linear V/F curve and two kinds of torque-reduction V/F curves, with manual and automatic torque lifting function | |

DC braking | Braking time: 0.0s~60.0s, braking current: 0.0%~100.0% rated current | |

Acceleration & deceleration methods | Linear acceleration & deceleration, S curve acceleration & deceleration | |

Jog | Jogging frequency range: 0.10Hz~50.00Hz | |

Automatic voltage regulation (AVR) | When grid voltage changes within a certain range, automatically maintain a constant output voltage | |

Automatic carrier frequency regulation | Automatically regulate carrier frequency according to load characteristic and environment temperature | |

Process PID | Process PID regulator can be set in 3 stages and can be disabled via terminal, and it provides PID correction mode and sleep function (applicable to water supply industry) | |

Spinning pendulum frequency function | For uniform winding displacement of spinning winding | |

Multistage speed method | It provides 7 stages of frequency selected by digital input terminal code | |

Others | Tracking start, stall prevention, oscillation suppression, accurate dead zone compensation functions | |

Environment |

Protection | Over-current, over-voltage, under-voltage, phase loss, output interphase short circuit, overheat, motor overload, external failure, lost connection of analog input, stall prevention, etc. |

Application site | With elevation below 1,000m, indoor, without direction sunshine, dust, corrosive gas, combustible gas, oil mist, water vapor, water drop, and salt mist, etc. | |

Operating ambient temperature/humidity | -10~+40℃/20RH~90%RH, without condensation water drop | |

Storage temperature | -20~+60℃ | |

Vibration | <5.9m/s2 (0.6g) | |

Structure | Degree of protection | IP20 |

Cooling mode | Force-air cooling |

Rated values, size and weight of Hope130 series inverter are as follows:

220V:

Inverter model |

Rated capacity (kVA) |

Output current rating (A) |

Adaptive motor (kW) | Chassis size (mm ) | Weight (kg) |

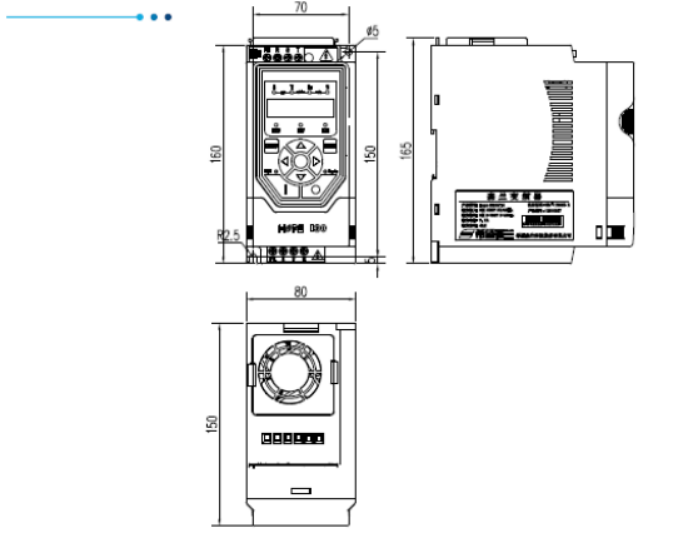

Hopel30G0.75S2U | 1.6 | 5 | 0.75 | 165*80*150 | 1.05 |

Hopel30G1.5S2U | 3.1 | 8 | 1.5 | 1.10 | |

Hopel30G2.2S2U | 4.2 | 11 | 2.2 | 1.15 | |

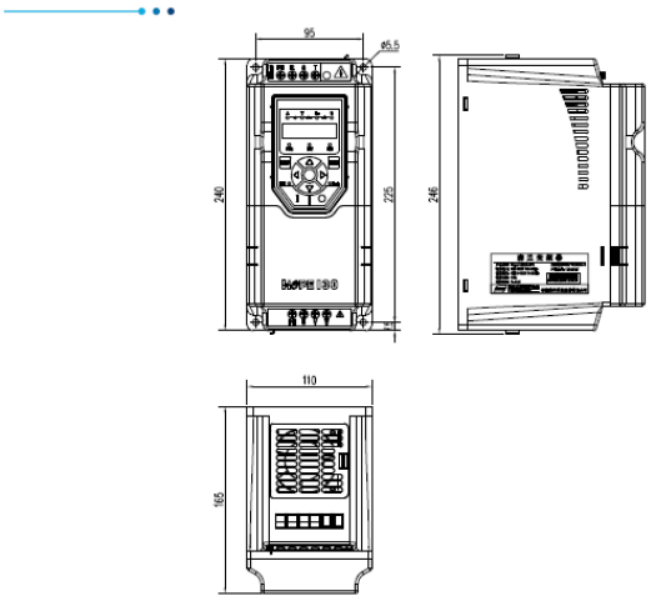

Hopel30G4S2U | 6.9 | 18 | 4 | 240*110*165 | 2.25 |

380V:

Inverter model | Rated capacity (kVA) | Output current rating (A) | Adaptive motor (kW) | Chassis size (mm ) | Weight (kg) |

Hopel30G0.75T4U | 1.6 | 2.5 | 0.75 | 165*80*150 | 1.05 |

Hopel30G1.5T4U | 2.4 | 3.7 | 1.5 | 1.10 | |

Hopel30G2.2T4U | 3.6 | 5.5 | 2.2 | 1.15 | |

Hopel30G4T4U | 6.4 | 9.7 | 4 | 1.25 | |

Hopel30G5.5T4U | 8.5 | 13 | 5.5 | 240*110*165 | 2.25 |

Hopel30G7.5T4U | 12 | 18 | 7.5 | 2.45 | |

Hopel30GllT4D | 16 | 24 | 11 | 280*130*180 | 3.2 |

Hopel30G15T4D | 20 | 30 | 15 | 3.8 | |

Hopel30G18.5T4D | 25 | 38 | 18.5 | 330*155*205 | 5.85 |

Hopel30G22T4D | 30 | 45 | 22 | 6.35 | |

Hopel30G30T4D | 40 | 60 | 30 | 400*195*222 | 10.45 |

Hopel30G37T4D | 49 | 75 | 37 | 10.65 | |

Hopel30G45T4D | 60 | 91 | 45 | 498*250*298 | 22.45 |

Hopel30G55T4D | 74 | 112 | 55 | 22.55 | |

Hopel30G75T4D | 99 | 150 | 75 | 611*280*318 | 30.6 |

Hopel30G90T4D | 116 | 176 | 90 | 31 | |

Hopel30G110T4D | 138 | 210 | 110 | 32.8 | |

Hopel30G132T4D | 167 | 253 | 132 | 715*360*315 | 50.5 |

Hopel30G160T4D | 200 | 304 | 160 | 51.35 |

Outline drawing and size of Hope130G0.75T4U~4T4U, 0.75S2U~2.2S2U up-in and down-out line model are shown below:

Outline drawing and size of Hope130G5.5T4U, 7.5T4U and 4S2U up-in and down-out line model:

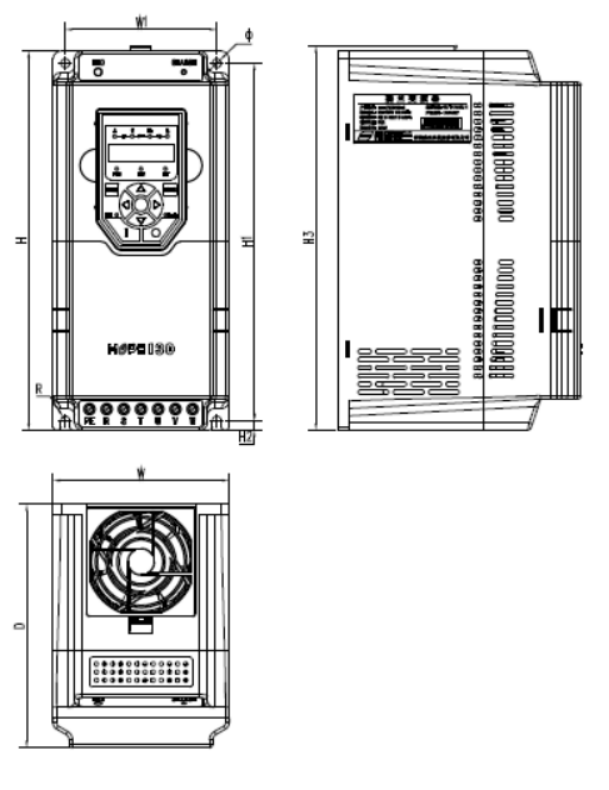

Outline drawing and size of Hope130G11~37kW down-in and down-out line model:

Inverter model | W (mm) | W1 (mm) | H (mm) | H1 (mm) | H2 (mm) | H3 (mm) | D (mm) | Φ (mm) | R (mm) |

Hope130G11T4D | 130 | 112 | 280 | 264 | 7 | 284 | 180 | 6.5 | 3.25 |

Hope130G15T4D | 130 | 112 | 280 | 264 | 7 | 284 | 180 | 6.5 | 3.25 |

Hope130G18.5T4D | 155 | 137 | 330 | 314 | 7 | 333.5 | 205 | 6.5 | 3.25 |

Hope130G22T4D | 155 | 137 | 330 | 314 | 7 | 333.5 | 205 | 6.5 | 3.25 |

Hope130G30T4D | 195 | 175 | 400 | 382 | 8 | 403.5 | 222 | 7 | 3.5 |

Hope130G37T4D | 195 | 175 | 400 | 382 | 8 | 403.5 | 222 | 7 | 3.5 |

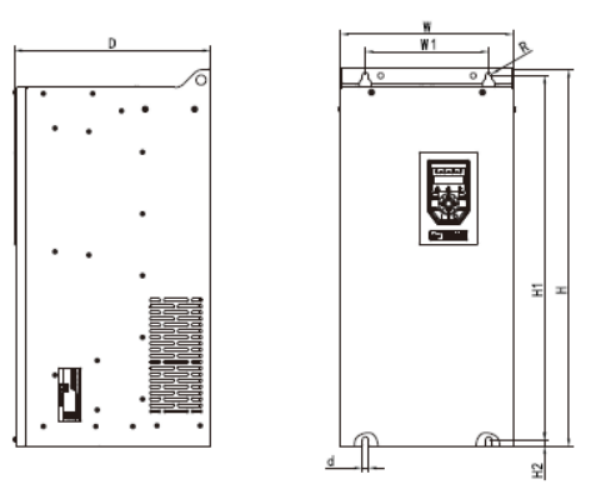

Outline drawing and size of Hope130G45~160kW down-in and down-out line model:

Inverter model | W (mm) | W1 (mm) | H (mm) | H1 (mm) | H2 (mm) | D (mm) | d (mm) | R (mm) |

Hope130G45T4D | 250 | 180 | 498 | 475 | 10 | 298 | 10 | 5 |

Hope130G55T4D | 250 | 180 | 498 | 475 | 10 | 298 | 10 | 5 |

Hope130G75T4D | 280 | 200 | 611 | 590 | 10 | 318 | 10 | 5 |

Hope130G90T4D | 280 | 200 | 611 | 590 | 10 | 318 | 10 | 5 |

Hope130G110T4D | 280 | 200 | 611 | 590 | 10 | 318 | 10 | 5 |

Hope130G132T4D | 360 | 280 | 715 | 695 | 10 | 315 | 10 | 5 |

Hope130G160T4D | 360 | 280 | 715 | 695 | 10 | 315 | 10 | 5 |